You have no items in your shopping cart.

- Divisions

- Manufacturers

- Quick Order

- Resources

- Tech Library

- Schematics

- New

-

Specials

- Back

- Flyers

- Closeouts

- Rebuilt Items

- Catalogs

- Agricultural Supply

- Air Equipment & Pneumatics

- Anhydrous Ammonia (NH3) Equipment & Parts

- Car Wash Equipment & Supplies

- Chemical Injectors, Dispensers & Mixing Systems

- Couplings & Adapters

- Deicing / Anti-Ice

- Engines, Motors & Power Transmission

- Filters, Strainers & Screens

- Fittings

- Heating & Cooling Systems

- Hose, Tubing, Reels & Accessories

- Lighting & Electrical

- Flow Meters & Gauges

- Spray Nozzles

- Petroleum Equipment

- Pipe & Pipe Fittings

- Plant Automation & Equipment

- Power Wash & Cleaning Equipment

- Pumps & Pump Systems

- Repair Parts

- Safety & Security

- Gas & Service Station Supplies

- Sprayers & Spray Equipment

- Tank Truck Equipment

- Tanks & Tank Accessories

- Tools & Material Handling

- Valves & Actuators

-

All Categories

- Back

- Agricultural Supply

- Air Equipment & Pneumatics

- Anhydrous Ammonia (NH3) Equipment & Parts

- Car Wash Equipment & Supplies

- Chemical Injectors, Dispensers & Mixing Systems

- Couplings & Adapters

- Deicing / Anti-Ice

- Engines, Motors & Power Transmission

- Filters, Strainers & Screens

- Fittings

- Heating & Cooling Systems

- Hose, Tubing, Reels & Accessories

- Lighting & Electrical

- Flow Meters & Gauges

- Spray Nozzles

- Petroleum Equipment

- Pipe & Pipe Fittings

- Plant Automation & Equipment

- Power Wash & Cleaning Equipment

- Pumps & Pump Systems

- Repair Parts

- Safety & Security

- Gas & Service Station Supplies

- Sprayers & Spray Equipment

- Tank Truck Equipment

- Tanks & Tank Accessories

- Tools & Material Handling

- Valves & Actuators

- Divisions

- Manufacturers

- Quick Order

- Resources

- Tech Library

- Schematics

- New

-

Specials

- Back

- Flyers

- Closeouts

- Rebuilt Items

- Catalogs

On-site service, installation, pump repair and portable welding in Omaha, NE

Full listing of products carried by Dultmeier that require Safety Data Sheets.

-

- G

- G&G LED Lights

- Gates Hose - Industrial

- GC Valves

- General Pumps

- Generant

- GF Georg Fischer

- GF Piping Systems - Georg Fischer

- Giant Pumps

- GinSan Industries

- Goodall Rubber

- Gorman Rupp Pumps

- Goulds Pumps

- Graco Pumps

- Great Plains Industries (GPI)

- Green Garde

- Green Leaf Couplers

- Greenleaf Nozzles

- Gusher Pumps

-

- Q

- QuickDry

-

- X

Hi-Line Co-op Project

by Seth Schulz | ©Dultmeier Sales

We wanted to share a recent Dultmeier success story that ultimately involved both our Omaha & Davenport locations, multiple departments, and a lot of hard work. This all started in the fall when we received a call from our mechanical contractor friends at AAK Mechanical requesting a quote on an 8X6 pump for a project they were quoting in Nebraska. We called Ron, who often helps with AAK requests, who then passed the information to Tom as we don't sell 8X6 pumps every day. AAK Mechanical informed us that this was for a W Design engineered rail unload project in Grant, NE for Hi-Line Coop.

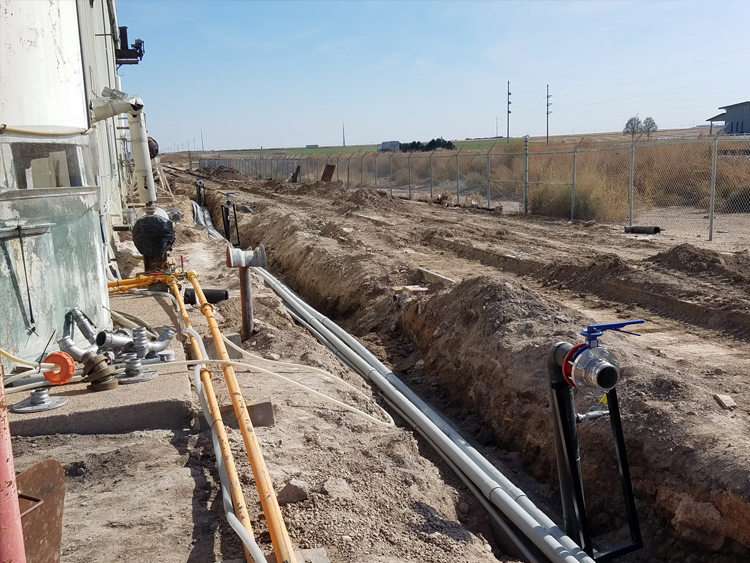

Buried HDPE Pipe

Once the entire scope of the project was realized, Mark took over as the point person on the project. Following Mark's initial conversation with the customer and W Design, it was determined that the goal was to unload 18 rail cars at roughly 1900 Gallons Per Minute. After determining the customer's needs, Mark and Tom went to work on sizing the appropriate pump for the job. Tom put on his engineering hat and ran multiple flow analysis until he found the right fit.

The initial plan was for Dultmeier to supply the pumps and for AAK or another mechanical contractor to do the entire install; however, a huge monkey wrench was thrown at us when all parties involved realized the timeline to get this done did not fit any mechanical contractors' availability and they all had to step away from consideration of doing the project.

Mark then met with the customer and W Design to find a solution and went to work on figuring out every part and piece the customer needed to install this project themselves. Purchasing got all components including the pumps ordered right away. Accounting made sure the account was in good order and that we would get paid. Distribution quickly turned the plumbing components around so the customer could begin the install work of the plumbing right away. Once the pumps were received, the production department began assembly of the units immediately.

More HDPE Pipe

Finally, our internal goal line was in sight as the pump units were getting their final touches added (check out the video below of our production department moving one of these massive pump units). Due to time constraints, the customer had to pick the pump units up before the final modifications could be done in-house. Production went the extra mile and Jeff made an early morning 5-hour drive to Grant, NE to personally install the final modifications. The project is now in the final stages as Mark makes periodic stops and communicates regularly with the customer to answer any final installation questions.

This project was a great example of every one of our core values - Customer Focused, Teamwork, Accountability, Drive Change and Character - being on full display to our customer. Furthermore, it shows that when everyone is pulling the rope in the same direction, we can accomplish anything.

150 HP 8X6 Pump / Motor

150 HP 8X6 Pump / Motor

150 HP Rail Receive Pump Installed

150 HP Rail Receive Pump Installed

$2500 FREE FREIGHT PROGRAM is for supplies, repair parts and whole goods. Tanks, pipe, sprayers and other large equipment are not included in this program. Applies to Continental U.S. ground shipments only.

Call for details! 1-888-677-5054

Close