The core values that drive Hydra-Flex are Innovation, Reliability, and Accuracy. These values are clearly visible in the products they develop. Hydra-Flex is proud to boast its reputation as "The Most Trusted Name in Chemical Dispensing".

Hydra-Flex is absolutely committed to focusing reduction of waste, salvage of resources, reduction in operating costs and the promise to provide exceptional - and measurable results for end users. Hydra-Flex is located in the Twin Cities area of Minnesota.

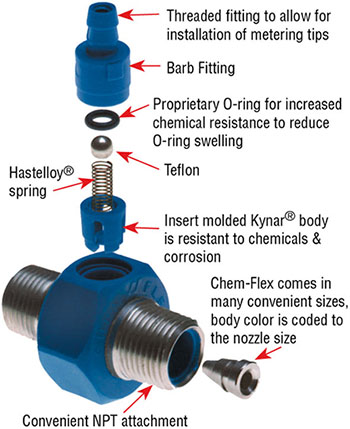

Chem-Flex Injectors

Hydra-Flex holds patents on chemical dispensing and nozzle technologies. The underlying premise of finding a "better way" to apply fluid handling technologies guides the Hydra-Flex strategy and solutions offerings. They have revolutionized the vehicle washing industry with their venturi design. While the concept of a venturi has been around for over 200 years, Hydra-Flex has taken this design to the next level.

Hydra-Flex created the Chem-Flex Injector to take venturi technology to the next level. Chem-Flex injectors use the most chemically-resistant and longest lasting components available on the market. This includes kynar venturi inserts, stainless steel connections, a hastelloy spring, teflon check ball and Hydra-Flex's exclusive XFC O-ring.