Did you or your customers apply the product labeled as Resicore last season? Any issues with elastomers in pumps, seals, fittings, etc. failing? We had quite the troubleshooting experience with this product over the past 2017 season. Our partner, Dura Products, has invested a significant amount of resources to ensure this problem has been resolved. We feel confident in their findings and want to make sure that you are well informed when working with this product.

In the 2017 season we sold a significant amount of Dura Auto Batch Systems and ran into some seal failures at the two to four week operation period. Failure from a Dura Product after such a short amount of time is extremely rare and once Dura Products was notified they immediately went to work finding the culprit behind these seal failures.

Testing and Findings

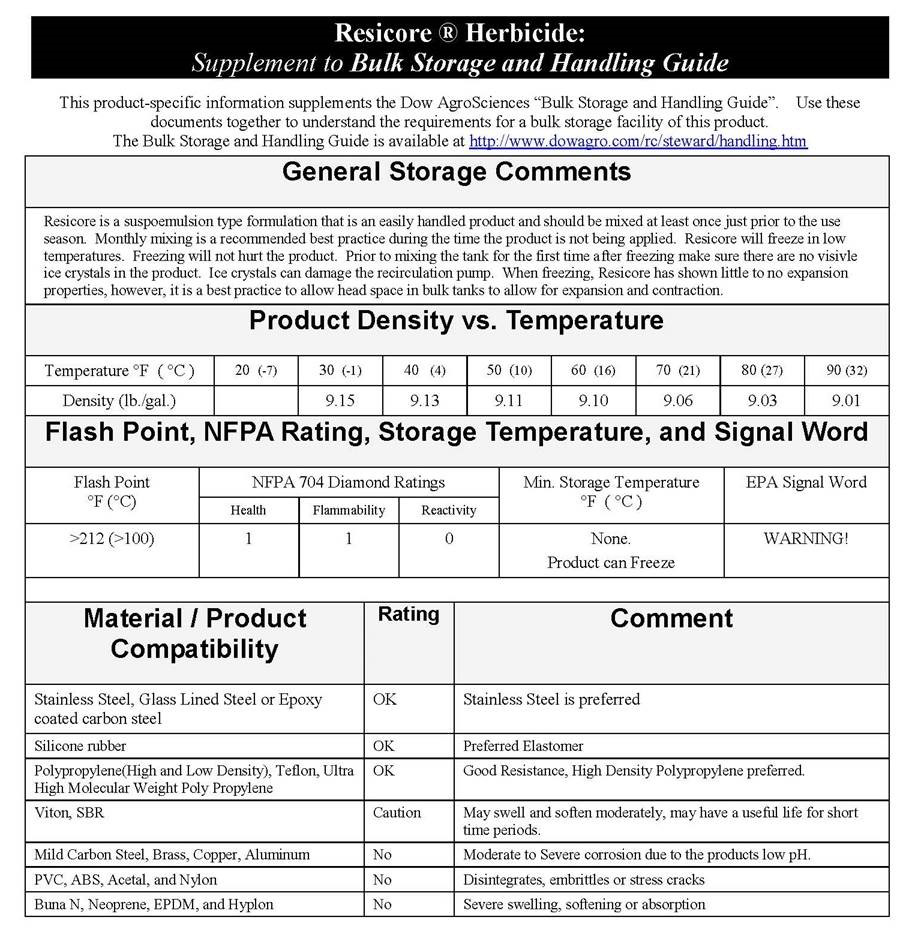

After weeks of research and testing, Dura Products concluded that the product, Resicore, could be causing the findings. Resicore is a Dow AgroSciences product which is used as a corn herbicide and was widely used in 2017 - there are thoughts that more will be applied in 2018. Once we were able to identify a common theme across these product failures Dura Products began testing multiple elastomers to determine their longevity when completely immersed in the solution. Here are the compatibility recommendations from Dow AgroSciences Bulk Storage and Handling Guide:

The only materials that are acceptable for constant contact and greater longevity with the product Resicore include stainless steel, Teflon, ultra-high molecular weight polyethylene (UMHW), High & Low-Density Polypropylene and silicone rubber. Of all these options silicone is the only elastomer that was found to be acceptable for constant contact- over an extended period of time.

Furthermore, it was found that polypropylene, a common plastic used in pump housings and pipe fittings, is actually only moderately acceptable. Dura Products' research found that polypropylene only lasts about 175 days before deterioration is evident.

The Solution For Resicore Transfer

We want to ensure that your products operate when you need them to operate and that they operate in the manner they are designed to operate. Research that Dow AgroSciences has provided and silicone elastomers that Dura Products has developed helps us to ensure that your operation continues to run smoothly.

If you are handling Resicore in the future you must be aware of the recommended compatibility of the wetted materials of construction for Resicore are Stainless steel, Teflon, Ultra High Molecular Weight Polypropylene, High and low-density polypropylene. The ONLY elastomer that you should be using is silicone.

Below is a photo of a soak test conducted by Dura Products: Viton seal on the left and Silicone seals on the right.

![]()

Throughout Dura Products testing and experiments, it was concluded that silicone was the best-suited elastomer for constant contact with the product labeled Resicore.

As you can see, Resicore has compromised the integrity of the Viton elastomer. It has also slightly discolored the O-ring. These are both clear identifying qualities of a chemical compatibility issue. Given the same testing parameters, the silicone elastomer held up just fine - as it is compatible with Resicore. Here is another blog post that further explains the importance of doing your research and homework to ensure chemical compatibility.

Whenever questions arise due to chemical compatibility, it's absolutely necessary to consult the material handling guide of the product you are applying or handling. In this instance, when reading the handling guide - Dow AgroSciences specifically states that stainless steel is preferred when transferring the Resicore product. The Resicore handling guide specifies these materials below:

Stainless Steel, Glass Lined Steel or Epoxy coated carbon steel - OK Rating - Comment: Stainless Steel is preferred.

Silicone Rubber - OK Rating - Comment: Preferred Elastomer.

Polypropylene (High and Low Density), Teflon, Ultra High Molecular Weight Polypropylene - OK Rating - Comment: Good Resistance, High-Density Polypropylene preferred.

Viton, SBR - Caution Rating - Comment: May swell and soften moderately, may have a useful life for short time periods.

Mild Carbon Steel, Brass, Copper, Aluminum - NO Rating - Comment: Moderate to Severe corrosion due to the products low pH level.

PVC, ABS, Acetal, and Nylon - NO Rating - Comment: Disintegrates, embrittles or stress cracks.

Buna N, Neoprene, EPDM, and Hyplon - NO Rating - Comment: Severe swelling, softening or absorption.

In Conclusion

Always make sure that you consult the label of the product which you are applying and/or handling. Furthermore, we are happy to continually be a source knowledge such as this blog post. If this post was useful and relevant please, don't hesitate to share it with your friends and colleagues. Take care.