Hydra-Flex History

Hydra-Flex was started in 2002 in a small machine shop. The company originated as a 2-man outfit and quickly grew in ranks from there. The core motivation for HydraFlex was driven by the simple belief to "find a better way" to produce innovative and reliable fluid handling products.

The core values that drive Hydra-Flex are Innovation, Reliability, and Accuracy. These values are clearly visible in the products they develop. Hydra-Flex is proud to boast its reputation as The Most Trusted Name in Chemical Dispensing.

This Eagan, MN company holds a committed focus to reduction of waste, salvage of resources, reduction in operating costs and the promise to provide exceptional - and measurable results for end users. Located within the innovative Twin Cities community, Hydra-Flex continues to strive for nothing short of exceptional product delivery.

Hydra-Flex is listed on Inc. 5000 Fastest Growing Private Companies and winner of Best in Class at the 2016 MN Manufacturing Awards.

Chem-Flex Injectors

Hydra-Flex holds patents on chemical dispensing and nozzle technologies. Also named one of Minnesota's Top Inventors by Twin Cities Business Magazine, Hydra-Flex continues to be recognized locally, as well as, nationally. The underlying premise of finding a "better way" to apply fluid handling technologies guides their strategy and solutions offerings.

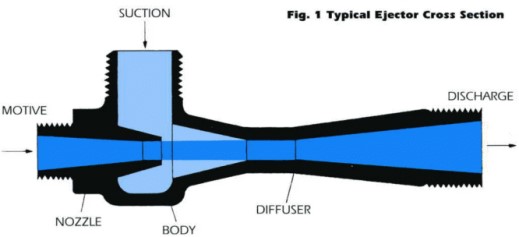

Taking a common design called a venturi, Hydra-Flex has revolutionized the vehicle washing industry. A venturi is not a new idea - the venturi was actually discovered by an Italian physicist, Giovanni Battista Venturi in 1797. A venturi induces a small portion of another fluid into a carrier fluid. This is created by creating a pressure differential between the inlet and outlet. Constricting the flow of the carrier fluid actually creates a vacuum, thus allowing the secondary fluid to be induced into the carrier agent. Furthermore, mixing the two fluids together through a venturi, ensures proper and equal mixture throughout the solution.

Hydra-Flex created the Chem-Flex injector to take venturi technology to the next level. Chem-Flex injectors use the most chemical-resistant and longest lasting components available on the market. This includes Kynar venturi inserts, stainless steel connections, a hastelloy spring, teflon check ball and Hydra-Flex's exclusive XFC O-ring. Chem-Flex injectors are built with the goal of finding a "better way" to induce and mix chemicals.

Benefits of Chem-Flex Injectors:

Small Footprint - Forget the need for large mixing tanks. Do it inline and mount these systems on the wall - maximize the space in your equipment room.

Better Vehicle Coverage - Using the same dilution rate but increasing delivery pressure allows for less solution usage and better coverage. Chem-Flex injectors have an application pressure capacity of 65-80 PSI versus traditional chemical dispensing systems that generally run from 25-40 PSI.

Consistency - Fluctuations in local water pressure do not affect the dilution rate of the injectors. Because the injectors use the pump's regulated pressure you need not worry about this variable. Thus, instilling a greater degree of consistency into your wash system(s).

Reliability - The simplistic design minimizes moving parts and, therefore, reduces the potential for failure due to mechanical wear. We have already mentioned the added chemical resistance brought on by the internal components used in Chem-Flex injectors - this is an added reliability factor. Rest assured - Chem-Flex injectors will stand up to some of the toughest chemicals on the planet.

Precision - Color-coded injectors (by flow rate) and metering tips (by dilution ratio) offer precise optimization and easy maintenance of the chemical delivery system.

Environmentally Friendly - Due to the fact that the solution is applied to the vehicle at higher pressure, less solution is needed to clean the same size surface. This often results in substantial reductions in water and chemical usage. Furthermore, the use of highly concentrated chemicals can help reduce packaging waste and freight costs. If you can order in smaller packages you can help reduce a variable cost in freight expenses.

The Nozzles

Hydra-Flex offers five models of nozzles - each one provides a solution to various industry applications. While there are five different models the nozzles can be split into two larger categories - Rotating Turbo Nozzles and Static, Zero-Degree Nozzles.

Rotating Turbo Nozzles

Blast-Tec Pro (1000PSI) - designed specifically for high-pressure, high-impact wash applications such as wheel blasters, undercarriage cleaning, rinsing and high pressure cleaning.

Ripsaw (3200PSI) - specifically designed for hydro-excavation industry. An extremely heavy-duty and high impact nozzle that is ideal for pothole applications. The cone-shaped flow patter provides 18 degrees of coverage.

Aqua-Rocket (4000PSI) - designed and engineered for the industrial cleaning industry. This nozzle blasts a concentrated 0 degree water jet while rotating at an optimal speed to form a 22 degree cone-shaped spray pattern. Here is a video below

Static, Zero-Degree Nozzles

Blast-Force (1000PSI) - This nozzle produces a solid-stream and was specifically designed for spinning, high-pressure vehicle wash applicators. Constructed with corrosion-resistance tungsten carbide nozzle orifices, this critter will get the job done - and then some.

Switchblade (3200PSI) - Dig Faster. Save Water. Another hydro-excavation nozzle but in a stationary in design. Cut deeper, cut faster. A neat feature of this nozzle is the flexibility it offers. There are individual, replaceable, color-coded nozzle pills that allow the end user to change water flow rates and pattern based upon various soil conditions. Here it is in action:

Whether you're in the market for nozzles or chemical injectors, you need to consider Hydra-Flex as a viable option in your decision making process. For further questions on other products we offer you can stop by our website any time you wish. Thanks for stopping by and we hope you enjoyed this post.