Whether it's 1980 or 2021 - Dultmeier Sales fields thousands of calls each spring on this topic alone. How do I size my spray nozzles? We don't help you select the type of spray tip for your application(s) - we advise you to consult your agronomist in this instance so they can get eyes on the crop situation to help develop a custom plan for your operation. That being said, once you've identified which type of nozzle(s) you need, we can absolutely assist in the sizing of said nozzles. This post is a great resource to use that helps to outline what we do just about every day during spring.

It's spring, and with the frenzy of field preparation, fertilizing, and putting seed in the ground on everyone's mind, the height of the planting season is nearly upon us. This time of the year also signals, if you haven't started already, that the time for you to begin readying your sprayer for your early season spraying is fast approaching.

Between calibrating your sprayer pump and checking all your hoses, you already have a lot to get done in order for your sprayer to be ready for the field. One of the most important parts of your sprayer prep; however, is ensuring that you have the correct sprayer nozzles appropriately sized for the chemical and fertilizer solutions you're looking to apply.

Without serious attention to detail, improper nozzle sizing can lead to a multitude of mistakes and delays when you can least afford them, not to mention the increased costs. In this article, we'll examine the proper approaches for how to size nozzles for various spray application types and how to attain ideal nozzle coverage and drift control. We'll also share why correct sprayer nozzle sizing is so important to your sprayer and crop performance. Read on at your leisure or use our table of contents to help you navigate through the article to find the answers you're looking for.

Contents

Nozzle Sizing Information to Know Before You Begin

Sprayer nozzle sizing can often be a confusing bit of business, especially with new tips and nozzles being designed every season. Pulse width modulation anyone? Luckily, the way you decide which nozzles you need has remained essentially the same for years. The first step is ensuring you have three pieces of critical information:

- Rate of application - in gallons per acre (GPA)

- Average sprayer speed - in miles per hour (MPH)

- Nozzle spacing - in inches (W)

Once you have those pieces of information nailed down, you can then plug them into a standardized formula and calculate how many gallons per minute (GPM) that you need to apply. Here's the formula:

GPA x MPH x W / 5,940 = GPM (per nozzle)

Knowing the number of gallons per minute you need to spray then allows you to reference a sprayer nozzle sizing chart that you can use to locate the ideal nozzle size for your specific sprayer setup. There are also plenty of tip sizing tools available online that calculate the best tip size for you. You can try our GPM calculator or use these from the nozzle manufacturers:

In the next section, we'll put this formula into practice and walk you through a few examples of how to size your sprayer nozzles for different chemical and fertilizer applications so you have a better idea of how to approach it on your own.

Sprayer Nozzle Sizing for Different Applications

Although sizing spray nozzles is largely uniform across the board, there are a few slight differences in how to size a sprayer tip depending on the type of liquid solution you're applying. Here, we've included the two most common application types when sizing broadcast nozzles: chemical/water solutions and liquids heavier than water.

Sizing for Ag Chemicals and Water Solutions

A vast majority of your sprayer applications will fall under this category since it includes most of your herbicides, insecticides, fungicides, and other common ag chemicals. Sizing nozzles for this type of application is also the most straightforward since you're using water as the base agent and aren't having to adjust for a higher relative density.

Relative density, also commonly referred to as specific gravity (SG), is the ratio of density-or mass of a unit volume-of a substance to the density of a standard reference material. For liquids, specific gravity is almost always measured against water since water has a specific gravity of 1.0. When calculating the application rate of liquids heavier than water, you must use a conversion factor to compensate for the higher solution density. We'll cover more on these conversion factors when we discuss sizing sprayer nozzles for liquids heavier than water a bit later. For now, though, assume that our examples are calculated with the SG of water.

Now, many sprayer nozzle sizing charts will display a wide selection of common spraying speeds. If your speed is already in the table, simply cross-reference your nozzle spacing and speed and locate the GPA you want to apply. But what if the speed you want to spray at isn't shown on the table? This is where the formula plays such an important role.

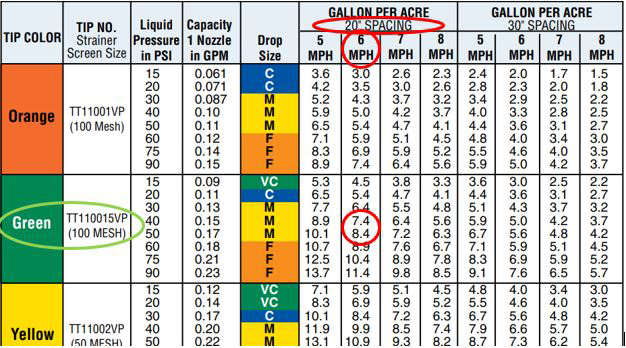

Shows how to find nozzle size for 8 GPA at 6 MPH for 20" nozzle spacing when all information is listed in the chart.

So, example time.

Let's say we want to spray 20 gallons per acre of 2,4-D. Our average sprayer speed in the field is 12 miles per hour (not shown in the table), and we are operating on 20-inch nozzle spacing. Our formula would look something like this:

20 x 12 x 20 / 5940 = 0.808 GPM (per nozzle)

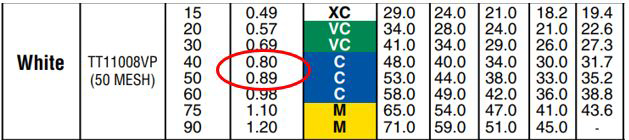

Let's also say that we want a course droplet size and are looking to use a Turbo Teejet wide-angle spray tip. Taking our 0.808 gallons per nozzle rate and using the Teejet sizing chart for this model of spray tip, we scroll down the Capacity in One Nozzle column to the nozzle size most closely matching our desired specifications. In this example, that would be the white tip nozzle.

It's best practice to find a nozzle that meets the GPM rate as close to the middle of the PSI range as possible. This is important in relation to your speed. Most spraying systems rely on largely consistent speeds across the entire field for the optimal performance. As a result, slow down too much, such as at the end rows, and you compromise your spray pattern and improperly apply your chemicals. Go too fast, and your sprayer pump may not be able to match your new pressure rate for the nozzles you have, setting off system alarms.

Even if your sprayer pump can match the higher speed, your droplet size then becomes much smaller, increasing your risk of drift. Neither case is what you want. Having a spray nozzle in the middle of the range ensures that you're able to maintain spray pattern, solution density, and droplet size-even with slight rises and drops in speed.

Sizing for Ag Liquids Heavier Than Water

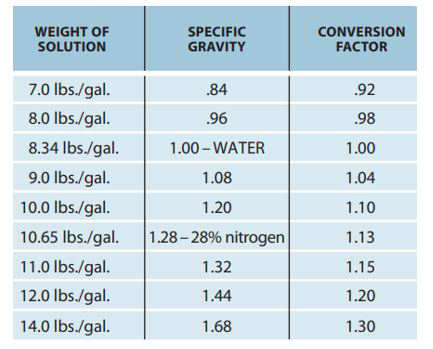

When sizing your spray nozzles for liquid solutions heavier than water, such as liquid fertilizer, you'll follow a very similar process as sizing nozzles for your water-based ag chemicals. The difference in sizing for this type of application; however, is that you need to adjust for the higher density of your solution. You accomplish this by using a density conversion factor seen in the chart below.

So, let's say we wanted to apply some liquid nitrogen fertilizer. Using the conversion chart above with our previous example, our formula would look like this:

20 GPA x 12 MPH x 20 W / 5940 = (0.808 x 1.13 Con. ) = 0.91 GPM

In this case, you'd still use the white nozzle tip from our previous example since the 0.91 GPM still falls near the middle of the pressure range for the course droplet size desired. If your speed is shown in the chart, simply take your intended GPA multiplied by your conversion factor to locate your nozzle size.

The key in either case is to factor in the conversion factor before you reference the sizing chart. Otherwise, you'll select the wrong spray nozzle and wind up with improper droplet size and inaccurate application. In the next sections we'll examine why these two ideas, spray coverage and droplet size, are tied so closely to the idea of proper nozzle sizing.

Nozzle Spacing and Spray Heights for Proper Coverage and Overlap

It should come as no surprise that sizing your spray tips correctly is just as important as where you put them on your sprayer. In fact, nozzle spacing and sprayer boom height are two aspects you mustn't ignore when choosing the size of the spray tip that you need.

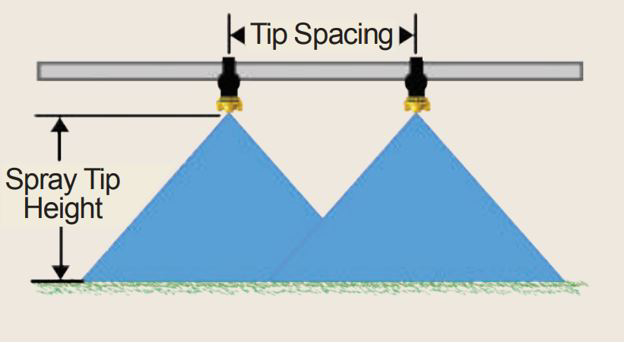

For starters, nozzle placement-both width between nozzles on the boom and the height of the nozzles above the ground-determines how well your spray coverage theoretically performs based upon the fan angle a nozzle has. Most setups will use some type of nozzle which creates a fan-shaped spray pattern. This means that the heaviest concentration of spray is at its center and tapers off to nothing at the edges. Common sprayer systems operate on 20, 30, or 40-inch nozzle spacing, and the arrangement of nozzles at these spacings determines how uniformly your application is ultimately applied.

To achieve uniform application; however, you'll need to create a pattern overlap in your spray coverage. Overlap-or the combining of spray patterns-is necessary, particularly in broadcast spraying, because the outer edges of spray patterns don't have uniform volume distribution. Without overlapping coverage, you risk leaving portions of your field under-treated or even skipped. That means you'll likely spend more time and money correcting the mistake.

Illustration of spray pattern overlap.

Factors that affect spray nozzle overlap

Three factors affect overlap in relation to sprayer nozzle sizing. First of all, your nozzle fan angle determines the total width of the spray pattern. The wider the fan angle, the wider the spray pattern. Today, 80-degree and 110-degree fan angles are the most used nozzle angles in agriculture applications, though others are available. Second, spray tip spacing. The closer the nozzles are to one another, the more the patterns will overlap. Farther apart, and the amount of overlap is lessened.

Finally, adjusting your spray tip height will further affect how much overlap you have. The higher the boom, the more overlapping because each pattern has more room to spread out. Another good thing to remember regarding the height of your spray tips is that the higher above the row your boom/tips are, the more susceptible to wind and drift your solutions are. We'll touch on this a bit more in relation to droplet sizing in the next section, but for now keep it in mind.

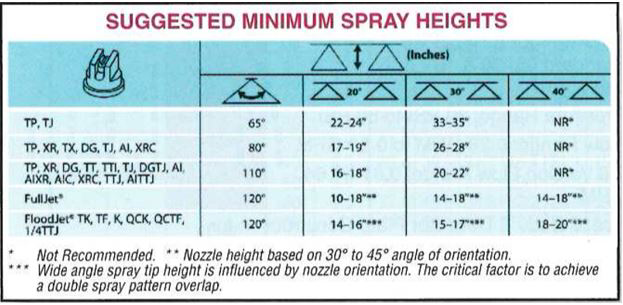

Now, unsurprisingly, not all spray nozzles are the same. Finding the proper height in relation to your nozzle spacing then is imperative. In the table below for example, you can see the height recommendations of various TeeJet nozzle series based upon nozzle fan angle and boom spacing.

In most cases, your ideal overlap for broadcast spray nozzles is approximately 30%. Adjusting your nozzle spacing and boom height accordingly will give you the best chance to maintain adequate, uniform coverage across the entirety of your system, even when other variables such as wind speed and pressure decreases occur.

Maintaining Droplet Size for Optimal Drift Control

Finally, we want to share a few words on droplet size. Namely, follow your labels.

After all, the label is the law! Not following how a specific chemical or pesticide is meant to be applied can create serious damage to not only your crops, but your fellow farmers' as well. This has become especially important when dealing with volatile chemicals like Dicamba.

Burn damage caused by Dicamba drift.

Make sure that you've chosen and sized a sprayer nozzle capable of producing the appropriate droplet size recommended for the chemical you're applying. If the label lists a specific nozzle or droplet size to use, follow those listings to a T. Furthermore, install your spray tips at the proper boom height and operate at the required pressure range to achieve the stated recommended droplet size of a given chemical. This will significantly reduce the likelihood you experience issues with 'hanging' droplets and drifting.

Consulting the spray label is just smart practice. It can determine whether or not you need to make any additional adjustments to your spray equipment or need to purchase additional nozzle accessories to attain the right nozzle spacing and droplet size specifications.

Importance of Proper Sprayer Nozzle Sizing

We don't have to tell you that your time is money. When it's time for you to be spraying in the field, you can't afford troubleshooting on the fly or stopping to recalibrate your sprayer a second or third time.

Which is the exact reason why you should take the time well in advance of spraying season to research the agricultural chemicals and fertilizers you intend to apply. Running long or short of chemical means your solutions were not applied efficiently and may not work as effectively as intended.

In fact, overapplication due to poorly sized or worn out sprayer nozzles is a serious problem if left unaddressed. Ag chemicals are very expensive, and if you're over applying it, you're wasting money. All the major manufacturers that we represent recommend replacing any spray tip if it's overapplying by 10% of the rate of a new nozzle. That includes TeeJet and Hypro to Wilger, Greenleaf, and Delavan.

If you find that at least two of your nozzles are overapplying by this rate anywhere across your boom, replace every nozzle in the system. Using a sprayer nozzle calibration tool, like the one shown below, will give you the fastest and most accurate reading of how your nozzles are performing and if you need to swap them out for new ones.

SpotOn Electronic Sprayer Calibrator, 0-1.0 GPM

Incorrect spray tip sizing has ramifications on your other sprayer components as well. Your sprayer pump especially may struggle to operate at its ideal performance. This can substantially increase the wear and tear on your pump components and lead to an inability of your pump to create or hold the spray patterns and proper application density.

Conversely, your pump outperforming your spray nozzles at higher speeds can change the droplet size. Higher pressures create smaller droplet particles and lead to increased risk of drifting that can cause serious damage to you or your neighbor's crops when dealing with many of the volatile chemicals used today. Be sure to routinely examine your sprayer tips for wear of the nozzle orifice for the reason that you ensure they aren't in need of replacement in order to maintain the correct droplet size you're after.

In the end, understanding how your agricultural chemicals and fertilizers are meant to be used and their proper droplet size ensures both appropriate solution application and adequate drift prevention. Once you have that information, the rest is relatively easy.

Conclusion

Although the science behind sizing sprayer nozzles has become more dynamic in recent years, the process doesn't have to be complicated for you. Following the guidelines in this article will give you a great start to your spraying season and ensure you aren't left reworking your sprayer when you should be in the field.

Be sure to check out our nozzle selection tool, or give us a call if you have additional questions regarding sprayer nozzle sizing. We offer a huge selection of TeeJet, Hypro, Greenleaf, Wilger, and Delavan spray nozzles to suit your unique sprayer setups. Our team of experts will be glad to assist you with any concerns or questions you may have and discuss how to ensure you're getting the best performance from your spray nozzles.

After all, we're your Experts in Delivering Fluid Handling Solutions - WE KNOW FLOW! ®