What do we look for in a sprayer?

Is it to merely kill weeds? How well does a certain sprayer kill weeds? The size - is bigger necessarily better? Or, do we also need to assess the value of that sprayer against how long it spends in each field? All these questions should be carefully considered when making a large investment into a piece of equipment that drastically affects the yield of your crop(s).

After all, a sprayer is one of your most important asset management tools when maintaining and ensuring your crop health - thus effectively ensuring that you get the most out of your yields - regardless of the crop you're raising. Therefore, I think the answer to the questions above is that we must absolutely consider each question when determining a true Return on Investment (ROI) for a sprayer - regardless of the operation size or scope.

In this write-up we will assess the four questions above. To start, let's dissect each question at a high, strategic level.

How Well Does a Certain Sprayer Kill Weeds?

This is a somewhat loaded question as chemical types, brands, and mix rates are involved. But if your accessory products/equipment, which are used to move the solutions onto the plants are lacking, then your sprayer effectiveness will undoubtedly be lacking, as well. Therefore, we must consider year-end maintenance programs. Boom-end flow rates, line obstructions in accessory products such as strainers and valves. Leaking pump seals, poor shaft alignment, and worn spray tips all factor into the efficiency and productivity of your sprayer. Neglect these important features of your sprayer and your operation, and your crop yields will undoubtedly suffer. So, to answer the question outlined in the opening paragraph - your accessory products, that are used to help move solutions, - are just as important to your operation as the sprayer itself.

Year-End Maintenance

It is necessary that a season-end maintenance program is followed to ensure your operation sees success in the ensuing season. Follow our recommended winterization process. Hoses, pumps, motors/engines, valves, strainers, and spray tips should all be inspected to help create a post-season inventory/repair list, in preparation of the upcoming season.

Spray Tip Selection

Have the proper spray tips been selected for the job(s)? Consult your local agronomist for specific details on the product(s) you will be spraying for the upcoming season. When spraying Dicamba products, only specific spray tips are approved for each product - and at specific pressure ranges. You can read another post related to Dicamba. Undoubtedly, always check the label of the product you are spraying to ensure you are spraying "on label". You can have all bases covered in preparation for an upcoming season. However, if you choose incorrectly on spray tips - or size your spray tip orifices incorrectly based upon the rates you intend to apply - the consequences could be catastrophic to your operation - or your neighbors' operations. Here is a tip sizing tool from TeeJet.

Sprayer Size

Does bigger necessarily mean better? It depends. If you're out in western Nebraska and have straight runs for a mile plus, then you may want to consider 120-foot booms with auto steer functionality. However, if you're in Western Iowa and you have many fields that are 75 acres or less, you probably want to opt into a smaller, more agile spray package. Regardless of your choice, one question should drive your purchasing decision - what is the potential ROI?

Speed and Efficiency

How long does it take to spray each field and how many acres do you anticipate covering daily? This should be one of the largest focal points when assessing your operation. Don't focus on non-productive time in an operational day (i.e. travel from field to field, rinse-out, rain/wind delays). These are variables that we have little to no control over.

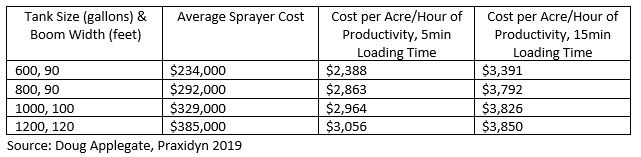

However, a large area in which we do have control over is nursing, or fill, times. If you can cut your fill times, regarding both fuel and chemical, how much more productive can you make your operation? Let's look at some products that can help you achieve this task. First, let's look at a study done by Praxidyn's Doug Applegate, regarding average sprayer price in comparison with cost per acre/hour. The numbers displayed reflect average prices/costs from various suppliers/operators in a regional area in Western Iowa.

Conclusions:

- Slower loading times increase the cost per acre/hour of productivity. Increased cost ranges from 26 to 42 percent.

- Spending 10% more for larger capacity/coverage in a sprayer will increase productivity roughly 8%.

- Spending 7% more for an automated mixing system can increase productivity by 20% to 30%.

- Smaller sprayers are actually more cost effective for their capacity.

The main takeaway here is that, in general, an operation can lower operating costs by, roughly, 20%. Let me repeat….20%. And by simply shaving off 10 minutes from fill times. It's important to note, as the sprayer size increases, the cost savings are reduced. For instance, a sprayer with a 600-gallon tank and 90-foot boom can effectively realize over 29% savings by reducing fill times down to 5 minutes. Consequently, when looking at a sprayer with a 1200-gallon tank and 120-foot boom, we see about 20% cost savings.

Praxidyn MixMate

The Praxidyn system allows users to automate loads. You can prepare loads the night before from your living room while watching TV or from an office chair. Send the loads to the operator in the field. No math needs to be done by the operator. The biggest change the operator would make to the load is regarding weed height. Upon arrival to the field, if the operator notices weed height on the order calls for six inches, and the weed height is actually 10 inches - the operator can make that adjustment to the order and the software will recalculate input quantities on the fly - no math is needed.

Another value-added feature to the MixMate system is the ability to track and record data. Through the cloud-based software, a user can record exactly how much product was applied to each field - and the exact time of the load or batch. This will continue to be ever-more important as regulations continue to tighten.

MixMate Fusion - New for 2019

We hope that you enjoyed this write-up on increasing sprayer efficiencies. Should you have any questions or feedback don't hesitate to get in touch with us at www.dultmeier.com!